Drinking straw making machine

The Drinking Straw Making Machine utilizes polypropylene (PP) and masterbatch as its primary materials for the production of clear, single-colored drinking straws. The manufacturing procedure consists of several stages, including melting, extrusion, molding, cooling, pulling, and cutting. This machinery is composed of a main framework, specialized tooling, a water cooling system, and a cutting apparatus.

Quality Control:

The operation of the machine is both smooth and quiet, attributed to precision-ground and hardened gears and bearings. The screw and barrel are crafted from Aluminum Chromolybdenum alloy steel and undergo stress relief treatments to improve their longevity. Additionally, a nitrogen hardening process is employed on the die to extend its operational life. The water tank and the cutting machine’s surface are made from #304 stainless steel. Moreover, the screw in the primary extruder is tailored specifically for the intended plastic material.

drinking straw

PP drinking straw

| Model | KD-11 | KD-12 | KD-13 |

| Colors | 1color | 2colors | 3colors |

| Screw dia | 50mm | 50mm | 50mm |

| Motor | 11kw | 11kw | 11kw |

| Power | 380v 50Hz | 380v 50Hz | 380v 50Hz |

| Output | 25-35kg/hour | 25-35kg/hour | 25-35kg/hour |

| Product length | ≥50mm | ≥50mm | ≥50mm |

| Product dia. | Φ4~12mm | Φ4~12mm | Φ4~12mm |

| Stripes | Straight | Straight or Helical | Straight or Helical |

| Product thickness | 0.05-0.3mm | 0.05-0.3mm | 0.05-0.3mm |

| Weight | 900kgs | 1000kgs | 1200kgs |

| Power Voltage | 220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Sudan 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Sudan 415V 50Hz…) | ||

| Machine Working Time | 24 hours * 7 days | ||

| Warranty | 1 year | ||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

PP drinking straw machines warehouse

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Loading Drinking Straw Machine Warehouse into container

Our Main parts cooperator as following brand,but standard parts all made from China.

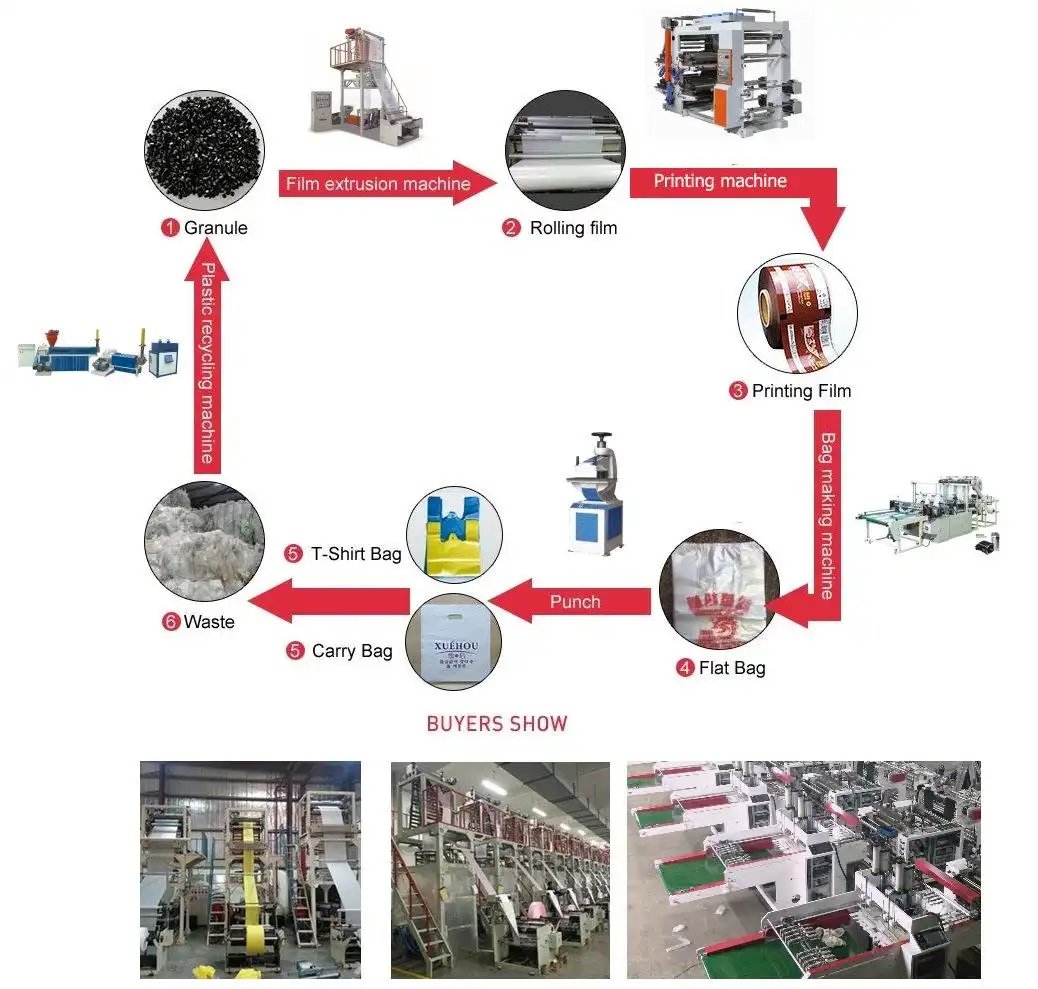

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;